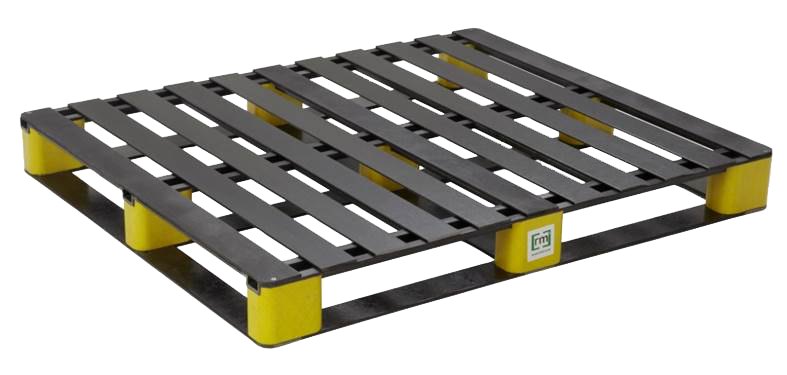

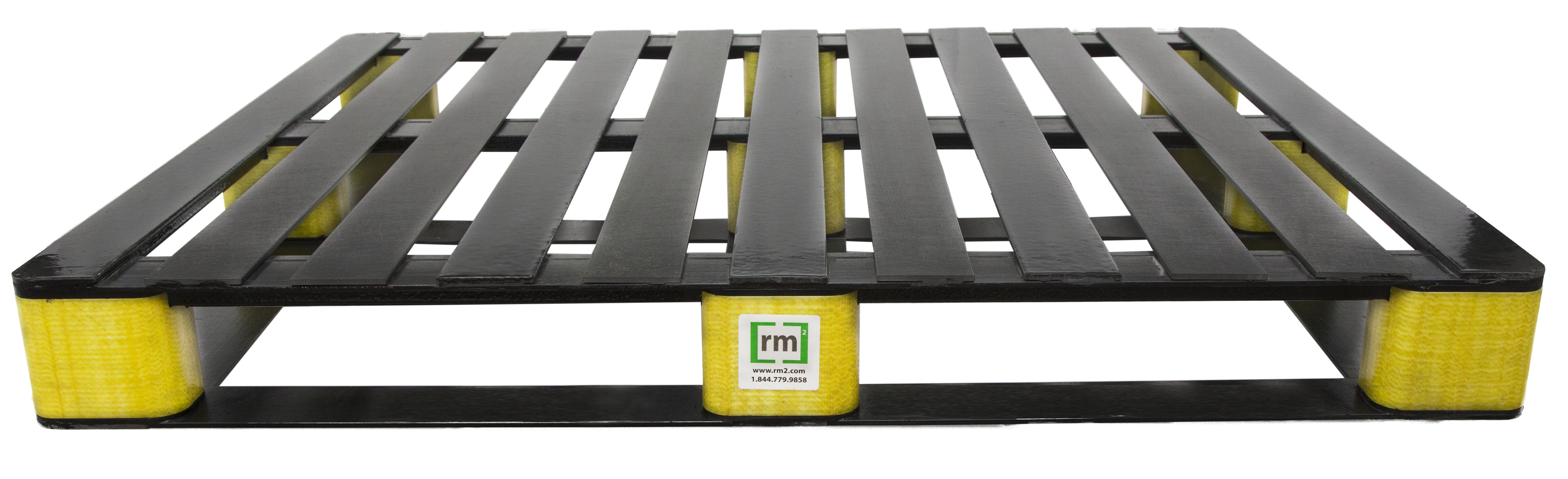

BLOCKPal™ REUSABLE BLOCK PALLETS WITH IoT TECHNOLOGY

Smart pallets, engineered for optimal performance in the world’s most demanding supply chains.

Download Spec Sheet

Made of a composite material that’s stronger than steel by weight, BLOCKpal pallets have an edge rack capacity of 6,500 lbs., more than twice that of other pallets, greatly reducing the risk of product damage or employee injury due to pallet failure. Independently tested to ISO 8611 and ASTM D 1185 standards and under the Virginia Tech Center for Packaging and Unit Load Design protocols to greater levels of durability than any widely available or comparable alternative.

Constructed with pultruded glass fiber reinforced composite, resistant to rupturing, fracturing, bending and deflection. Precise, automated construction ensures consistent dimensions (maximum allowed dimensional deviation is 0.635 MM).

Low profile runners and wide, 4-way fork openings make for easy handling; non-slip coating on both sides of top deck offering greater coefficient of friction in ambient environments for both product and forklift tines.

Non-porous surface resistant to moisture, bacteria, pests and chemicals; easily cleaned with no heat treatment nor caustic chemical cleaning agents required.

Every BLOCKPal pallet features embedded RM2 ELIoT® technology. Location and condition data are collected by sensor and transmitted to the cloud via the LTE-M network, making visible the pallet’s location and condition both indoors and in transit without requiring any additional hardware or IT development.

Low profile 5.0″ height allows 90 more BLOCKpal pallets per backhaul truckload, reducing transportation costs by 17%, and weight of 55 lbs. vs. an average of 70 lbs. for other block pallets makes both handling and transport more efficient.

o -40° to 176° F tolerance range exceeds that of other pallets by more than 20° in each direction, so it won’t become brittle in cold environments or flexible in hot environments for dependable performance in a variety of conditions.

Constructed of FM4996 certified, naturally fire-resistant material with no carcinogenic additives.