REUSABLE PALLET CLEANING AND LOGISTICS

RM2 has the reusable pallet manufacturing, cleaning, and logistics capabilities to service high volume customers in the world’s most demanding supply chains.

REUSABLE PALLET MANUFACTURING

The RM2 BLOCKPal is a precision engineered reusable pallet made with sophisticated materials in a high-tech manufacturing environment. Beginning in 2016, manufacturing has been outsourced to world-class partners with state-of-the-art facilities.

Precision Engineering

The pallet is engineered for strength and durability, with the similar technology, composites and high performance adhesives used to keep fighter jets and airliners safe at 40,000 feet.

Production Capacity

RM2's manufacturing partners have the capacity to produce nearly 1 million BLOCKPal pallets per year to service our growing demand.

State-of-the-art-Processes

The BLOCKPal manufacturing process can be broken down into three distinct processes: pultrusion, fabrication and assembly.

PALLET CLEANING

RM2 utilizes three strategically-located pallet cleaning facilities in the US to service its hygiene-sensitive customer needs, each with the capacity to wash over 1 million RM2 pallets each year.

Automated Pallet Cleaning Process Ensures Consistency

BLOCKPal pallets are washed in standardized machines in an automated two-step process which ensures consistent cleaning and drying of the pallets.

Strict Food Safety Protocols

RM2 pallets are washed using the same effective cleaning agent specialist food companies, catering companies, and food preparation businesses use for sanitisation of their production facilities and equipment. Pallets are washed in a high-pressure mixture of the agent and water in a conveyer-driven automated washer at a temperature of 130° F. The washing mix is computer-controlled and calibrated a with a chemical titration test to validate the exact molecular amount per given volume of water tested. This is then followed by a high flow rate fresh water rinse to remove residual chemical followed by a high volume air drying process.

ATP Swabbing Confirms Hygiene

After the wash process is complete, pallets are swabbed to confirm ATP readings of 50 or below.

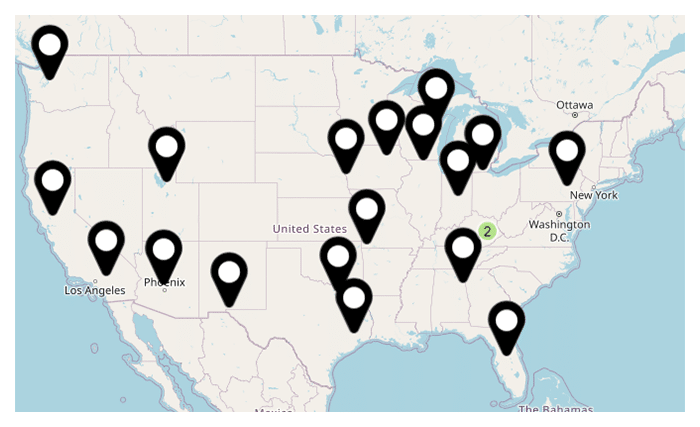

LOGISTICS AND SERVICE NETWORK

RM2 utilizes a nationwide network of over 19 strategically-located logistics and wash depots to minimize the transportation miles needed to service our customers.